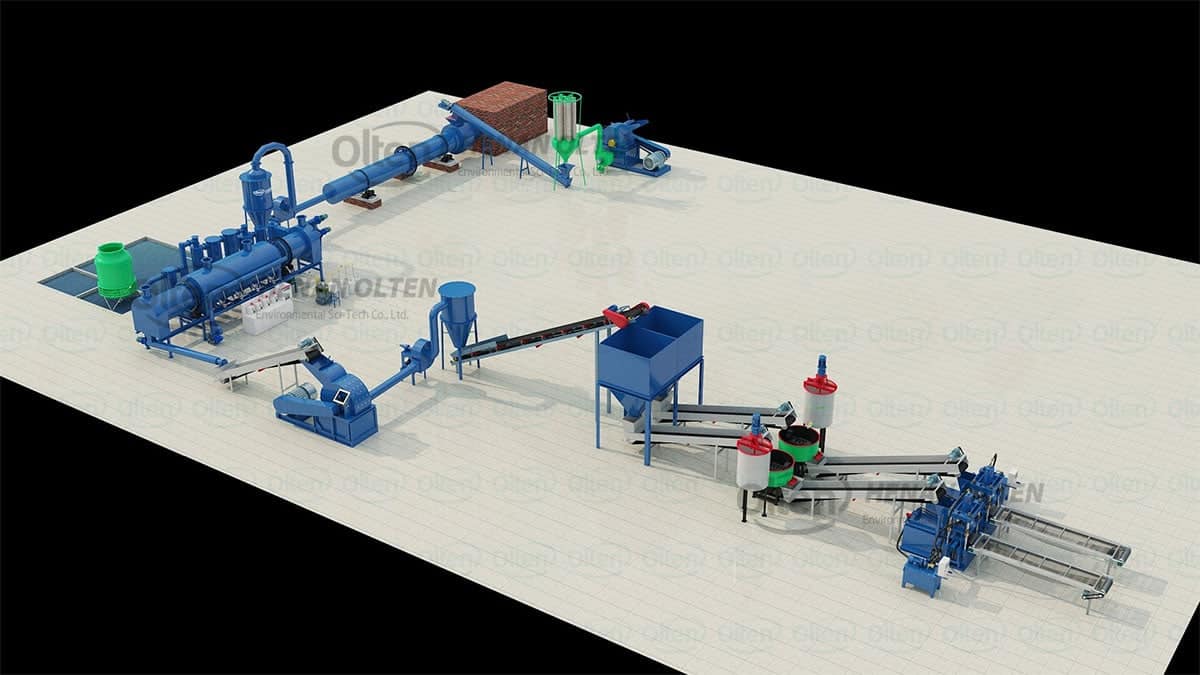

When using a charcoal machine to manufacture mechanism charcoal, the carbonization furnace equipment is an important piece of equipment to have on hand. The carbonization furnace equipment's operation technology is also critical in the production of mechanism charcoal. As a result, proper operation of the continuous carbonization furnace China furnace equipment used to produce the mechanism charcoal can ensure the quality of the charcoal and prevent the failure of the equipment itself. Increase the amount of money that is made.

There are several methods for carbonizing shisha charcoal briquette machine furnace equipment, which can be divided into two categories: internal combustion method and dry distillation method. Internal combustion method is the most commonly used method. Low temperature discharge temperature, high temperature calcination, and cooling and cooling are the three stages of carbonization. The continuous carbonization furnace manufacturer process is divided into three stages:The carbonization temperature should be kept between 550 and 600 degrees Celsius. When the salary bar is introduced into the carbonization furnace equipment, it contains approximately 8% water, and this moisture is detrimental to the carbonization process. For the simple reason that the salary bar is afraid of getting wet. The tidal time for the earthen kiln is typically 10-15 hours, and the tidal time for the kiln is 2-3.5 hours. The prolonged heating time can prevent the salary bar from becoming cracked as a result of moisture intrusion and ensure the quality of the continuous carbonization furnace wholesale process itself. When the temperature of the furnace rises to 300 degrees Celsius, a significant amount of combustible gas can be generated in the furnace. These gases have the potential to be used to heat the furnace. Disconnect the heat source from the drying process. It is necessary to seal the oxygen-free closed fire when the temperature rises above 400 degrees Celsius for the heat preservation calcination stage. It is possible to use either self-ignition cooling or water cooling. In order to avoid carbon dioxide poisoning, it is necessary to ventilate the charcoal after it has been discharged from the kiln and then add charcoal. More than 8 hours should be spent outdoors after the charcoal has been removed from the kiln, to prevent re-ignition and subsequent fire.

carbonization furnace5 (high-resolution image)

The quality of charcoal charcoal is closely related to the quality of the raw material rod used in its production

Generally speaking, the density of the raw material rod should be greater than one in order to be effective

The following is a simple detection method: immersing a formed raw material rod in water until the specific gravity of the water sinking is greater than 1, the specific gravity of the water floating is less than 1, and the density is greater than the major density, indicating that the charcoal produced is of high quality

As a general rule, the working principle of the continuous carbonization furnace supplier furnace equipment is as follows: first, introduce the combustibles (such as sawdust, wood scraps, etc.) into the gasification furnace, and then, after spraying, cooling, purification, and other processes, introduce the flammability generated by the flue gas generated after combustion in the pipeline. After being heated and charred by gas, which served as the heat source for the previous carbonization, the raw materials used to make the 1#, 2#, 3#, and 4# carbonized tubes in a single-row or double-row combined shell carbonization furnace (such as rice husk, sawdust, straw powder, husk, palm shell, hemp, and so on) are charred. During the carbonization process, the flue gas produced is completely recovered, and the subsequent combustible gas produced is subjected to secondary combustion through the use of spraying, cooling, purification, and other methods. Through this method of circulation, the self-generated flammable gas is burned by itself, resulting in energy conservation benefits. The smokeless gas is discharged throughout the manufacturing process and complies with all applicable national environmental protection regulations. When the carbonization furnace equipment was invented, it not only helped to protect the environment, but it also helped to turn waste into treasure, which resulted in increased wealth for the general public. It is a high-quality piece of equipment that offers numerous benefits. When the shell shisha charcoal briquette machine furnace was used, it resulted in an increase in output, a reduction in carbonization time, and smokeless gas pollution in the production environment, resulting in energy savings and the transformation of waste into treasure.

The following are the most important factors influencing carbonization and carbon removal rates: the type of raw materials used, their density, and the temperature at which charcoal briquette machine occurs. The denser the charcoal mature material is, the better the final product will be. The carbonization temperature is low, the carbon removal rate is high, but the carbon smoke is large and the corrosion is increased; the carbonization temperature is high, the charcoal is brittle and easy to bend and crack; the temperature range is 550 ° C - 650 ° C, the friability and the solid carbon content are high; the temperature range is 550 ° C - 650 ° C, the friability and the solid carbon content are high; the temperature range is 550 ° C -Premium carbon has a solid carbon content greater than 80% when everything is perfectly balanced.

The method and principle of carbonization production of carbonization furnace equipment described above are applicable. Users must correctly operate the carbonization furnace equipment to produce charcoal mechanism in order to improve the quality of the charcoal produced, and the production of carbonization furnace equipment also results in an increase in the number of customers. Benefits in terms of money.