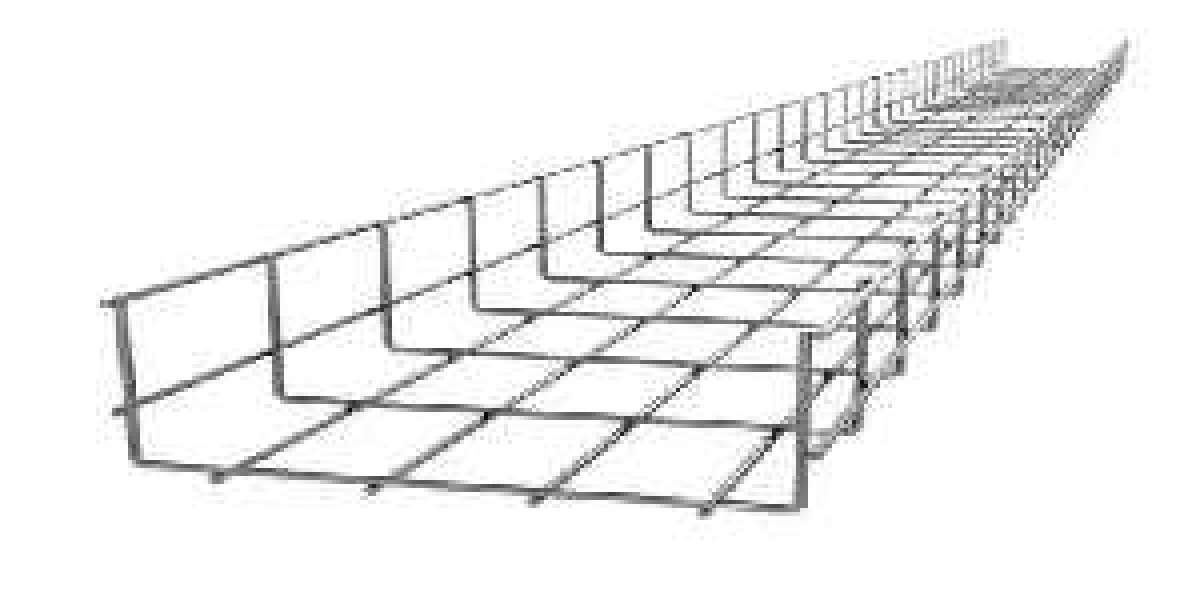

In the dynamic landscape of industrial infrastructure, wire mesh cable trays play a pivotal role in ensuring efficient cable management. When it comes to sourcing top-quality wire mesh cable trays, it's essential to identify the industry leaders who combine expertise with innovation. In this comprehensive guide, we present an insightful exploration of the top wire mesh cable tray manufacturers, focusing on Jeetmull Jaichandlall (P) Ltd, Wire Mesh Manufacturers, and GI Perforated Sheet Manufacturers.

Jeetmull Jaichandlall (P) Ltd: Setting Industry Standards

Introduction

They stand out as a stalwart in the realm of wire mesh cable tray manufacturing. With a rich history spanning decades, this company has consistently delivered products of exceptional quality.

Product Range

The diverse product range offered by them includes wire mesh cable trays designed to meet the specific needs of various industries. Their commitment to precision engineering ensures that the trays are not only durable but also tailored to handle the complexities of cable management.

Quality Assurance

One of the distinguishing features of it is its unwavering commitment to quality assurance. Each wire mesh cable tray undergoes rigorous testing to meet and exceed industry standards, providing clients with a reliable and robust solution for their cable management needs.

Wire Mesh Manufacturers: Craftsmanship at Its Best

Craftsmanship

When it comes to wire mesh manufacturing, precision and craftsmanship are non-negotiable. Leading wire mesh manufacturers, including them, prioritize the art of crafting mesh that not only ensures structural integrity but also facilitates optimal cable organization.

Material Selection

Wire mesh, being the backbone of cable trays, demands meticulous material selection. The industry leaders understand the significance of using high-quality materials such as stainless steel and galvanized steel, ensuring longevity and resistance against environmental factors.

GI Perforated Sheet Manufacturers: Enhancing Cable Tray Functionality

Perforated Sheets in Cable Trays

GI perforated sheets contribute significantly to the functionality of wire mesh cable trays. They allow for effective heat dissipation and airflow, preventing cable overheating and ensuring a safe working environment.

Customization Options

Top manufacturers recognize the diverse requirements of different industries. As GI perforated sheet manufacturers, they offer customization options, allowing clients to tailor their cable trays to specific dimensions and perforation patterns, ensuring a seamless fit within their infrastructure.

Conclusion

In conclusion, navigating the realm of wire mesh cable trays requires a keen understanding of the top manufacturers and their offerings. Jeetmull Jaichandlall (P) Ltd, Wire Mesh Manufacturers, and GI Perforated Sheet Manufacturers stand as pillars of excellence, providing solutions that redefine cable management.