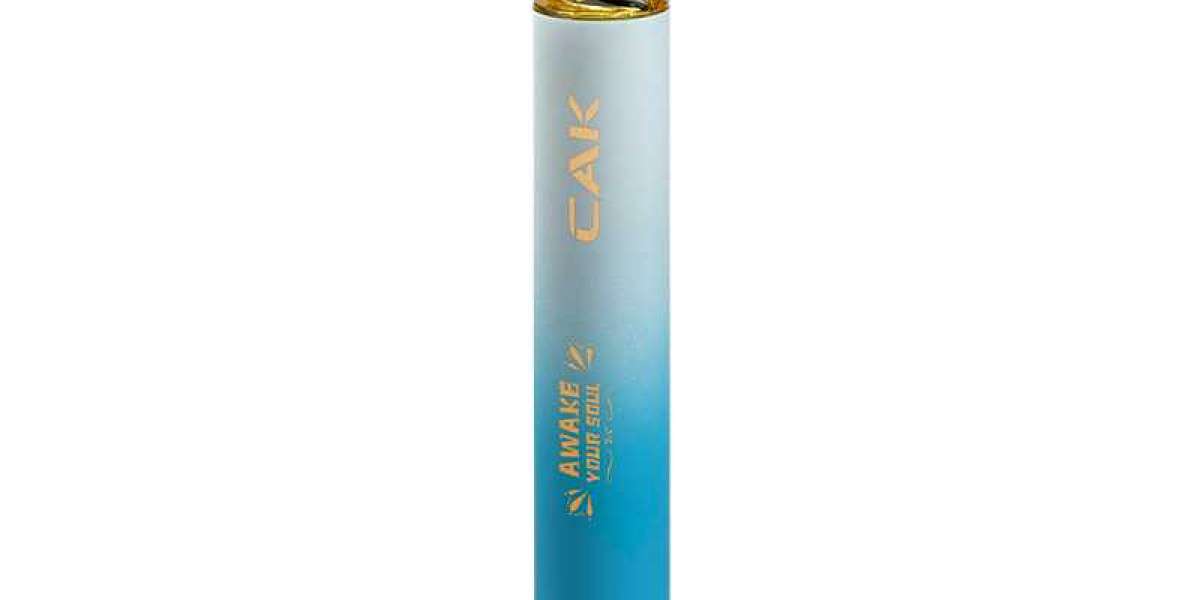

Vape is an electronic product that can replace cigarettes. In order to distinguish the look of various other vapes and also boost the marketing point of their items, enterprises will try to find commercial design firms to make the look and also framework of the items, and ultimately create item models.

Whether it is vapings, household devices, 3C digital, smart phone peripheral products, the manufacturing procedure of their appearance as well as body normally calls for lots of actions to develop an attractive look. As far as common flat cigarettes are concerned, the most effective shade paintings and also magic grooves presently on the marketplace are aluminum alloy bodies, which are integrally developed, and afterwards undertake surface area treatment such as anodizing and also sandblasting. Different from aluminum alloys, vape materials consist of stainless steel, zinc alloy, plastic, glass, ceramics, and so on. During the processing of these smokeless cigarettes, surface area modern technology is generally called for to form a lovely look.

When it involves the handling innovation of the hand version of smokeless cigarettes, there are currently six usual ones: polishing, sandblasting, laser carving, splashing, anodizing, as well as steel illustration. The editor of the e cigarette layout company will speak about each look. The features of the production process.

6 Seed Tobacco Look Design Refine

- Sandblasting.

The surface area of the substrate is roughed up by the effect of high-speed sand flow. Using pressed air as power, a high-speed jet is formed. It is quickly sprayed right into the surface area of the workpiece to be treated to transform the look or form of the workpiece surface. As a result of the impact as well as cutting activity of the unpleasant product on the surface of the workpiece, the surface of the workpiece can obtain a certain level of cleanliness and also different roughness. The performance is boosted, therefore boosting the tiredness resistance of the workpiece, increasing the longevity of the coating film, lengthening the resilience of the finish movie, and assisting in the progressing and decoration of the coating.

- brightening.

Brightening describes making use of mechanical, chemical or electrochemical activity to reduce the surface roughness of the work surface, so regarding acquire a brilliant and also smooth surface. The surface area of the workpiece can be processed using rough particles or various other polishing media and tools.

- laser inscription.

Based upon numerical control modern technology, the laser is utilized as the tool, and also the laser is made use of as the processing medium. Under the irradiation of laser engraving, the processing material is instantaneously thawed, evaporated and also other physical denaturation, to ensure that laser inscription can be refined. Laser inscription is using laser modern technology to etch message on items. Words etched by this procedure will not leave traces, the surface of the things is still smooth, as well as the writing will certainly not break.

- Metal cable illustration.

Steel cable drawing is a process in which the aluminum plate is continuously scratched with sandpaper. The procedure is separated into three components: degreasing, sanding, and also water washing. Throughout the stretching procedure, after plating, a special movie technology is made use of to create a film having this metal element on the steel surface area, so that every tiny silk mark can be plainly presented, making the metal matte. Reveals fine-grained sparkle. In recent years, increasingly more steel cases utilize metal cord drawing innovation, which contributes in looks and also rust resistance.

- spraying.

When spraying paint, with the help of a spray gun or a disc sprayer, with the help of stress or centrifugal pressure, the droplets are uniformly distributed on the surface of the object to be painted. Various acquired types such as high circulation, reduced stress atomizing spraying, thermal splashing, automated spraying, multi-component splashing, such as large circulation as well as low stress atomizing spraying, thermal splashing, automated splashing, multi-component spraying.

- Plating.

Electrochemical oxidation of metals or alloys. With a particular electrolytic service and also particular procedure problems, an oxide film is formed on the surface area of light weight aluminum as well as its alloys. Unless or else specified, it normally describes sulfuric acid anodizing.