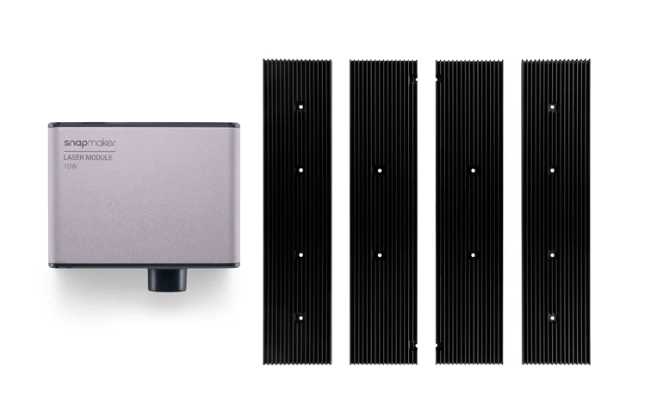

10W High Power Laser Module is just that perfect add-on that transforms your Snapmaker machine into a powerful 3D laser cutter machine. The 10W laser module only costs $498, which is an average industrial price.

The 10W Laser Module is outfitted with the most cutting-edge laser beam splitters, resulting in a power increase from 5W to 10W. This means you can now experiment with more materials and complete more projects.

Meanwhile, the 10W Laser Module has a lightning-fast speed of up to 6000 mm/min and can cut through basswoods as thick as 8 mm. In simple terms, the cutting speed is up to 8 times faster than the 1.6W Laser Module. It can do a laser job in the blink of an eye. With this kind of fast speed, the 10W laser module is a really powerful laser module for CNC.

The module initially compresses the laser spot of each laser diode using the Fast-axis Collimating (FAC) lenses included in the two laser diodes. Then, it employs beam combining technology to combine the laser beams of the two laser diodes, producing a higher output power and an ultra-fine laser focus (0.05 mm x 0.2 mm), which enables a higher energy density. High-quality laser works with perfect details are produced with a smaller laser focus and more power.

As the laser beam cuts into the material, the unique wind channel inside the 10W Laser Module creates excellent wind pressure that blows away the fumes. The fumes are sent directly into the grids of the Laser Engraving and Cutting Platform, where they get channeled out and lessen interference from laser machining.

No more measuring materials by hand. The module will compute it for you after you place your material on the platform. The module can measure the thickness of your material by acquiring several sets of data from the camera and light emitter using the triangulation technique. Then, it will change its Z orientation so that the focal point lands precisely on the surface of the material. In a few seconds, you can finish focusing.